Quality Control

OTAO tempered glass screen protector undergo 100% manual inspection before shipment.

Quality Control

OTAO had established one full SOP and TQM of quality control to check each raw materials, procedure, and product, making sure deliver in time, and guarantee the quality of each product.

Especially OTAO has experiences in building owned brand and served brand clients, OTAO has assembled precisely machines of production and full sets of test machine for each procedure, at the same time, expanding QC team, optimized each procedure, and added more procedures to qualify.

Check the raw material

We order qualified glasses 1000*1000mm sheet from the bigger famous glass factory, not leftover, scrap material and wasted material.

All materials will be inspected before entering our warehouses and will be inspected before Cutting procedure.

Different quality standard of OTAO screen protector

The inspection process involves: pull testing, UV testing, vibration testing, and cyclical testing

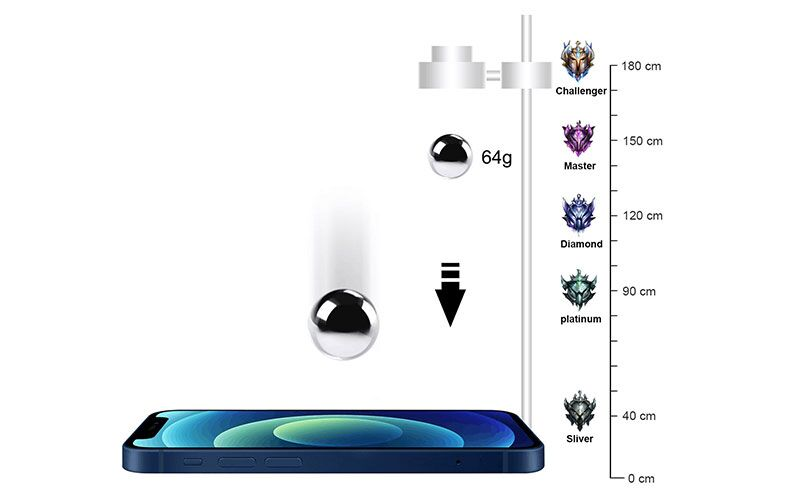

Steel drop ball test

Put the glass need to be test on the test baseboard,use 64g steel ball,40cm high/120cm high/180cm high,free falling at the center 3 times(falling test past percent is 80%),the glass can keep safe.

Abrasion test

AF oil make anti-rub test, the condition of AF is :

1KG load

0000#steel wool

wool touch size10mm*10mm

frequency50R/min

test over 3000 times /5000times

AF oil spray/AF electroplate

AF craft have electroplate and spray two types:

The effect of AF electroplate is 3~6 months

The effect of AF spray is 1~3 months

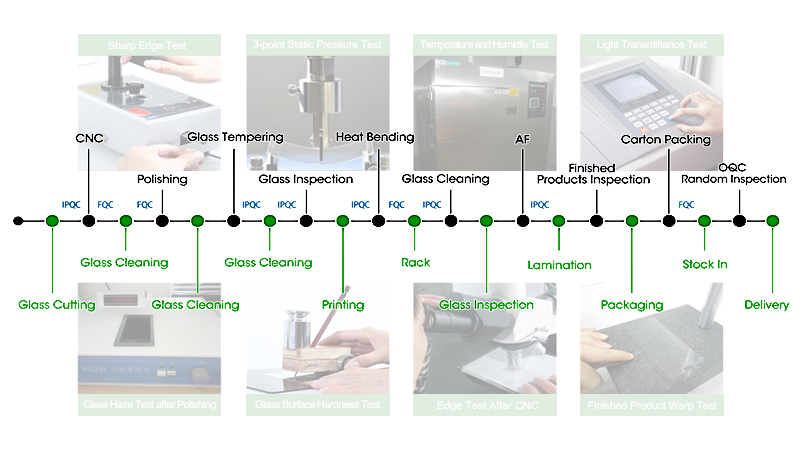

Production and testing of OTAO Screen protector

OTAO screen protector has passed 20 processes, 12 tests, and four times 100% full inspections by people before packaging and shipment. During these processes, we strictly control only to receive first-class quality tempered film for our customers.

Supersonic wave washing

Clean up the product after the polishing process,aviod there is polish flour still on the glass,can improve the high transmittance of tempered glass.

It can more accurately pick out scratched and chipped products on the glass.

Tempered effect:

Tempered will change the cover chemical composition to improve the hardness of the glass,it is use ion exchange method(K ion and Na ion change).

The good tempered glass screen protector was broken will break into one piece and will not splash and hurt people. The smaller the fragments, the better the tempering effect.

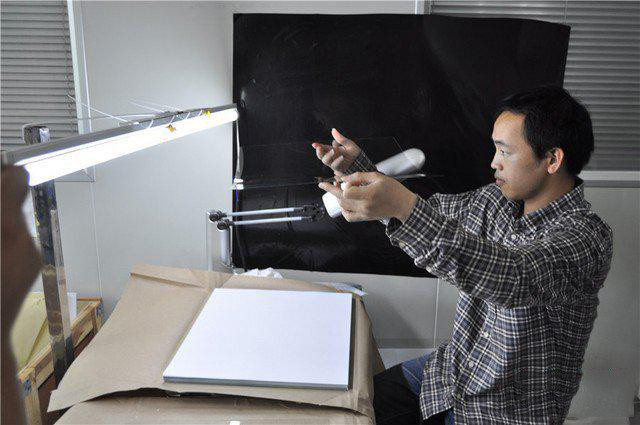

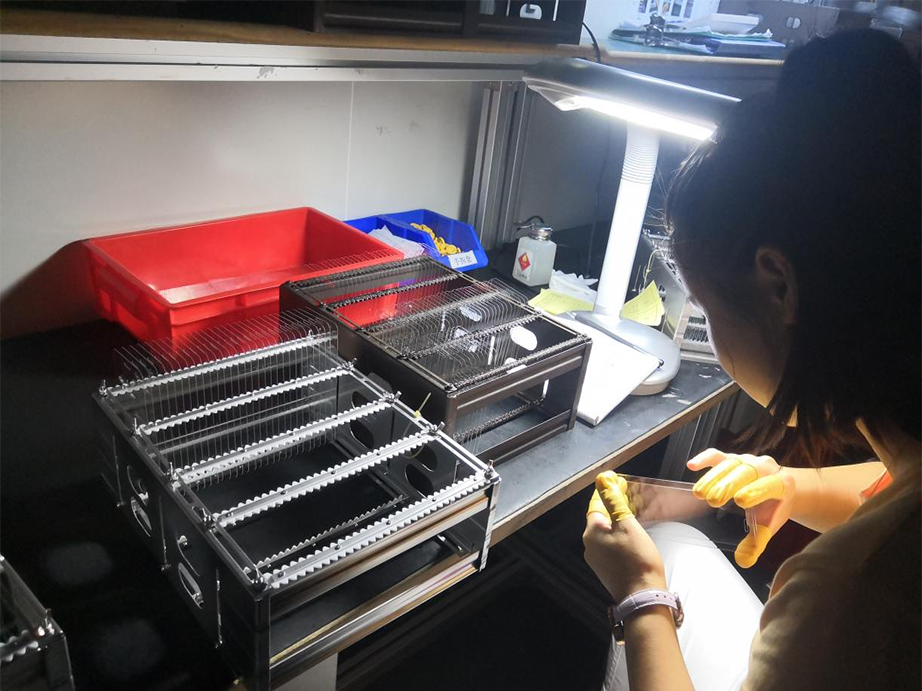

4 times 100% full inspections by people

Each piece of tempered film is inspected by workers one by one under light to eliminate defective products such as edge chipping, poor screen printing, dust spots, bubbles, etc.

OEM/ODM for Brand Clients

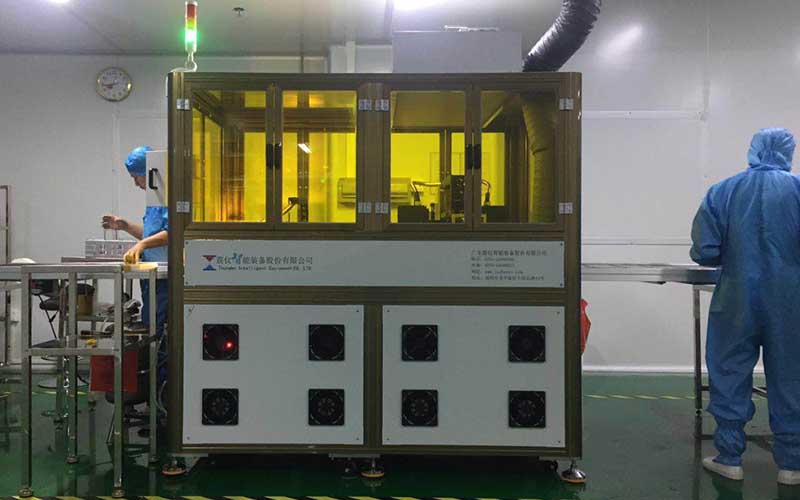

OTAO has owned a 12000sqm factory, 200+ workers, and hundreds of precise machines. The effective scaled precise production certified by BV, SGs, lsO, etc. to guarantee the quality and ensure to deliver in time.

OTAO served 300+ OEM brand clients with rich experiences and quality evidence, provided the related service of demand matching,design, solution, price, production, shipping, marketing, and support after-sales.